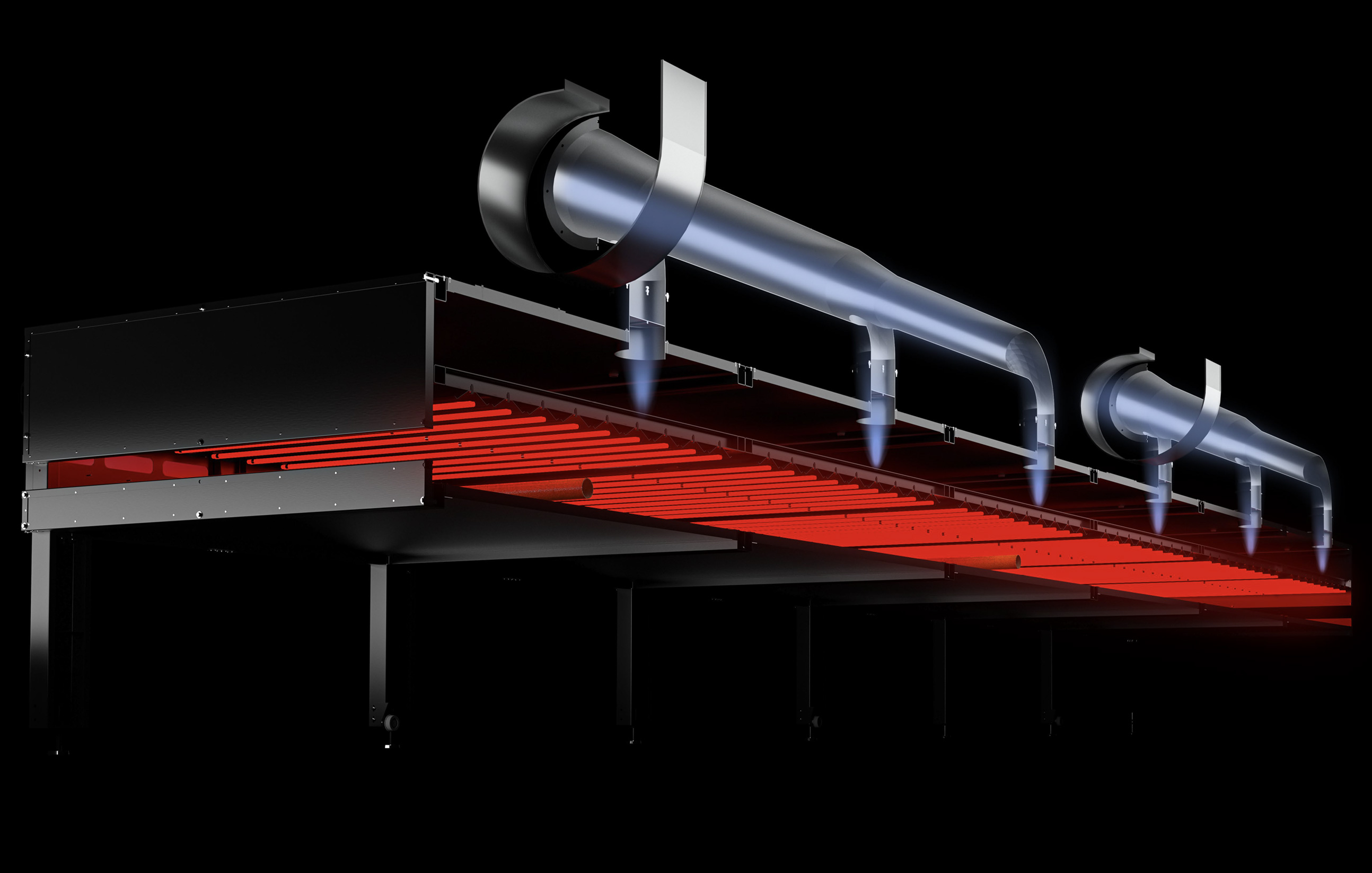

Tunnel IR

It is the ideal solution when a steam generator or a dedicated gas line (LPG or methane) is

not available and the electricity comes from alternative sources to fossil fuel.

The drying of the hides is monitored in real-time as it is regulated on the grain

temperature, detected by special laser sensors. Specific electronic controllers allow a

precise modulation of the power of the lamps, variable according to the temperature of the

hide’s surface.

The infrared lamps are made with a double gold coating of the upper part, in order to obtain

maximum reflectance and higher energy efficiency.

The air and humidity inside the tunnel are conveyed outside through a dedicated suction

system designed to allow internal air circulation which largely limits the deposit of

evaporation mixtures on the lamps and, being always filtered, precludes any deposits of dust

on the hides.